-

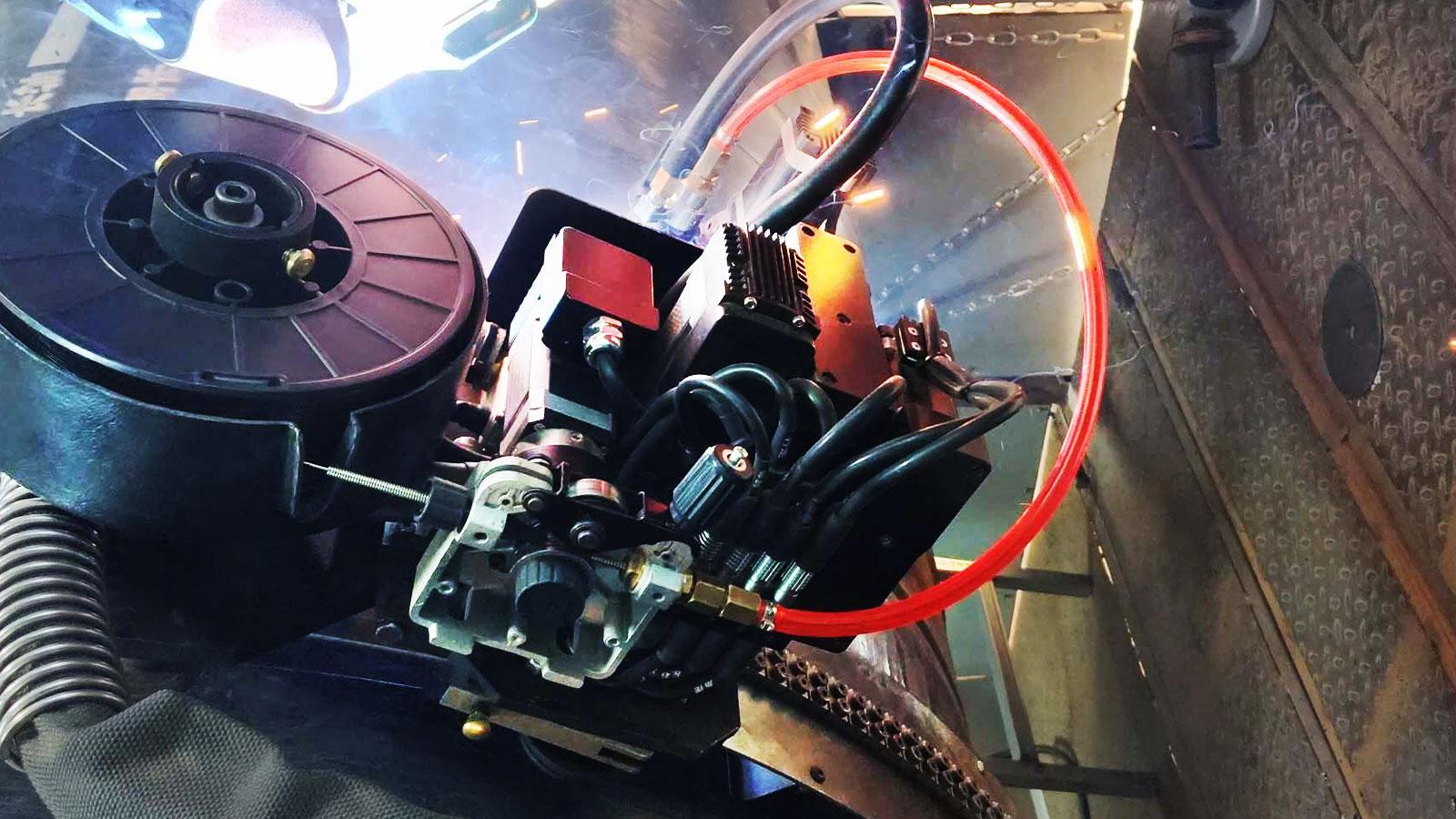

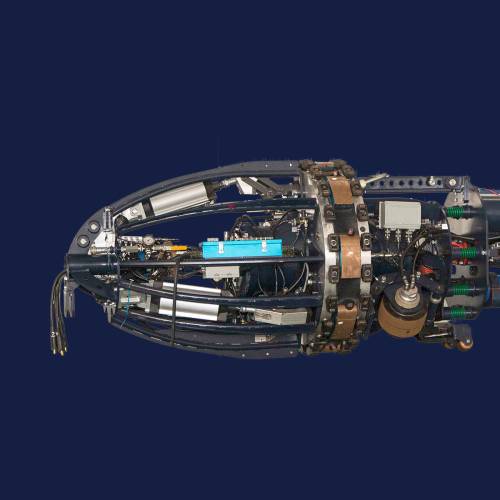

一、单枪自动焊机采用的导向轨道为齿孔式钢质轨道,其刚度强、重量轻、装拆方便。

- The guide rail of single torch automatic welding machine is made of perforated steel rail, which has strong rigidity, light weight, and convenient assembly and disassembly.

-

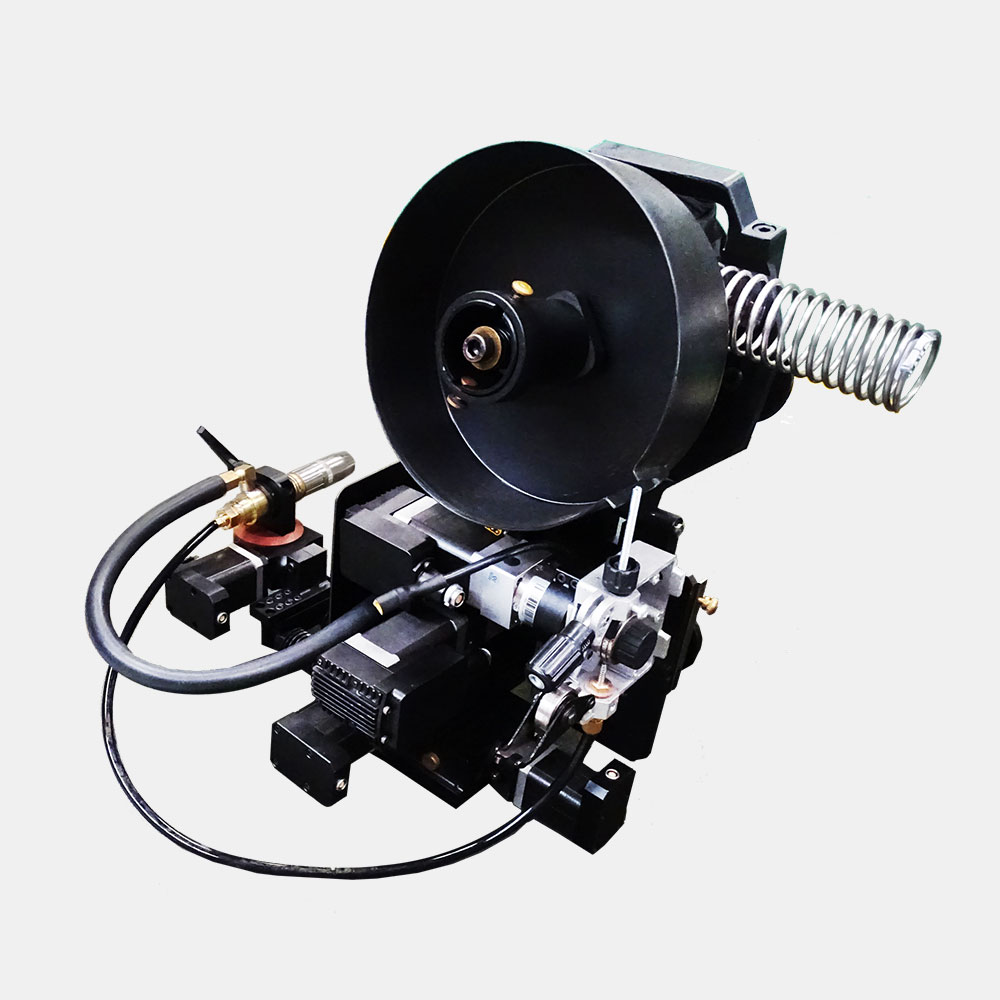

二、焊接小车重量轻、防尘性好、装夹便捷。

- .The welding trolley is lightweight, has good dust resistance, and is easy to clamp.

-

三、小车与轨道间采用单齿轮齿条方式传动,传动平稳、传动精度高(不丢转)。

- The transmission between the trolley and the track adopts a single tooth gear rack transmission method, which is stable and has high transmission accuracy (without losing rotation).

-

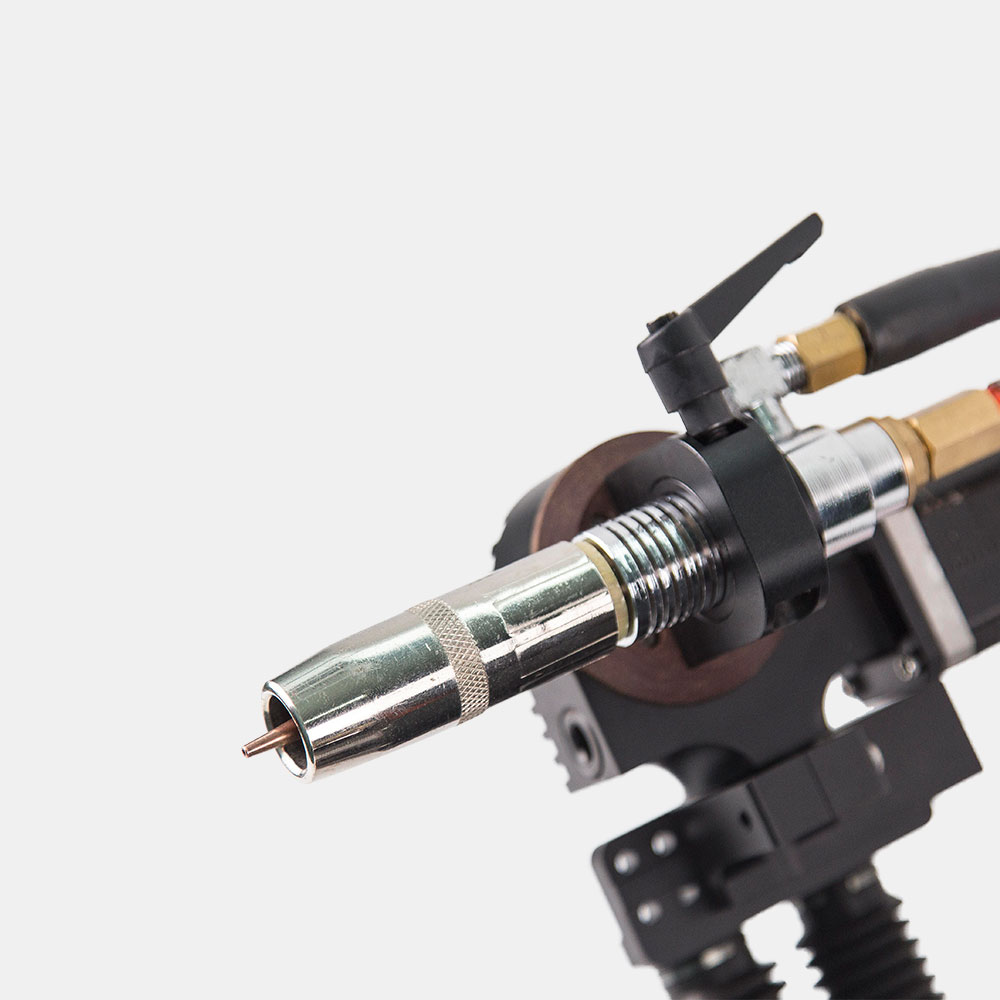

四、焊枪垂直水平位置均可调节,根据熔池的对称度调整焊炬,使焊接效果达到最佳。

- .The vertical and horizontal positions of the welding torch can be adjusted, and the welding torch can be adjusted according to the symmetry of the molten pool to achieve the best welding effect.

-

五、导向轨道采用分体式环形结构,可保证行走精度,安装简便。

- The guide rail adopts a split type ring structure, which can ensure walking accuracy and easy installation.

-

六、焊接过程中焊接小车的焊接参数均随着焊接位置的变化而变化,圆周各点参数均由自动控制程序完成,可实现焊接工艺参数的自动调整。

- .The welding parameters of the welding trolley during the welding process vary with the welding position, and the parameters of each point on the circumference are completed by an automatic control program, which can achieve automatic adjustment of welding process parameters.

-

七、采用可视化触摸屏用于焊接参数的设定、显示、修改与存储,支持数据的上传和下载。

- 7.Using a visual touch screen for setting, displaying, modifying, and storing welding parameters, supporting data upload and download.