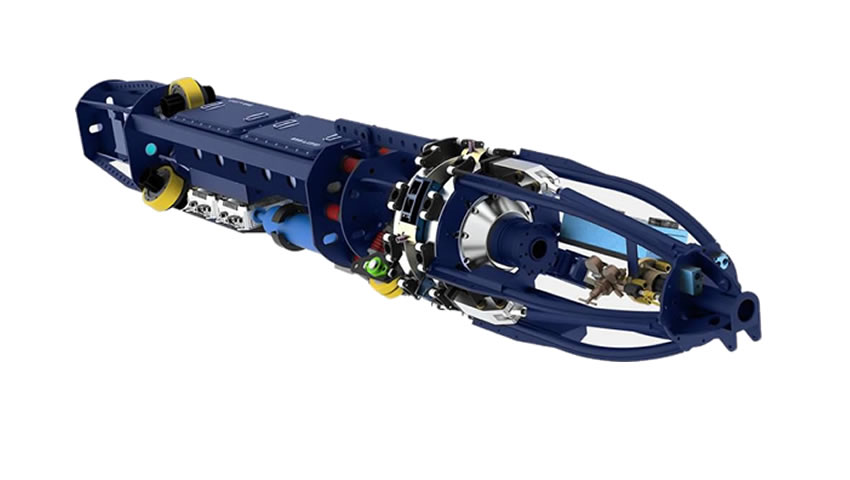

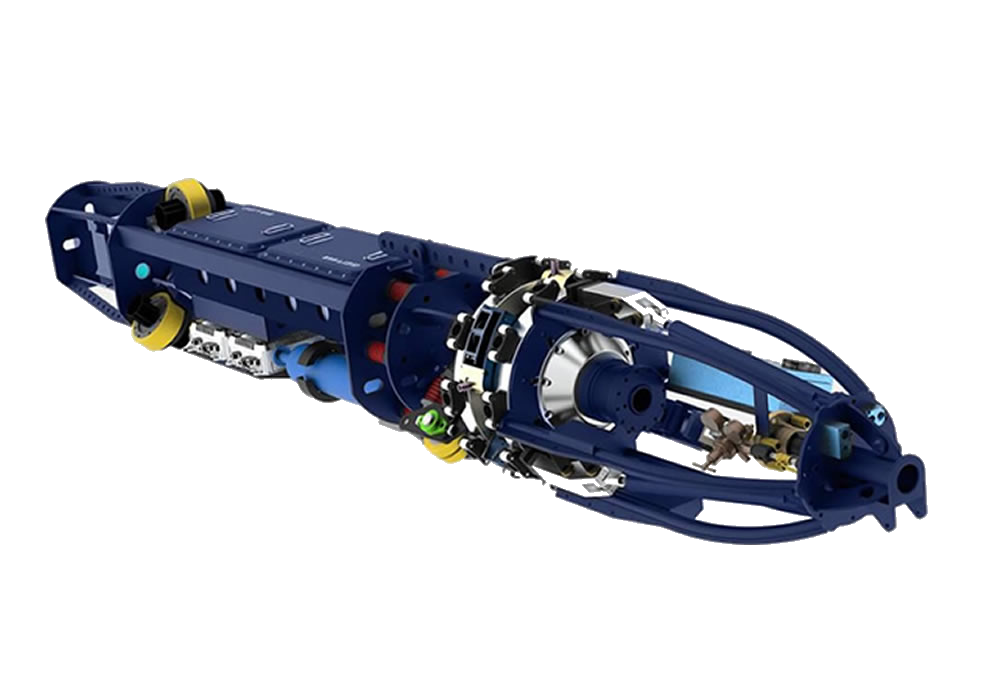

Simple instruction for PK series beveling machine:

The PK series pipeline end face beveling machine is suitable for pipes with diameters ranging from 323mm to 1422mm, with a maximum beveling wall thickness of 36mm

The product is applied to:Pipeline field construction in industries such as petroleum, chemical, natural gas, electricity, water conservancy, medical, and marine.

Performance characteristics:

- Long distance pipelines, prefabricated pipeline production lines, internal expansion grooves, and end face grooves

- Internal expansion hydraulic tightening mechanism: fast and automatic centering, strong tightening force, replaceable tightening module to achieve cross pipe diameterexpansionand centering;

- Inner wall tracking floating tool holder: The tool floats and cuts along the inner wall of the pipe, effectively ensuring an accuracy of ± 0.05mm on the groove surface of the processed pipeline

- Triangle alloy blade: The three edges can be cut to effectively increase the service life; Blade cutting speed 110m/min, cutting thickness 0.2-1.0mm

- No need for cutting liquid cold cutting;

- Modular control system: easy to operate, beautiful and elegant panel.

- Cutting feed: Independent module control achieves stable and reliable cutting feed and reverse movement

- Cutting power source: Adopting double large torque cycloidal hydraulic motor internal gear transmission, it has small volume, strong power, low energy consumption, low noise, and strong reliability.

- Inner and outer wall polishing brush: One process simultaneously completes the welding seam joint groove and polishing

- Suitable for groove processing before fully automatic welding of long-distance pipelines;

- Suitable for prefabricated production lines, onboard and field construction operations

- Hydraulic pump station: It is the power source provided by the hydraulic pipeline end face beveling machine. Our company adopts a lever mounted hydraulic station, which can be selected from internal combustion and electric types. Internal combustion is suitable for outdoor operations, while electric type is mainly used for ship or prefabricated pipeline operations.

- The end face beveling machine can be customized with pure electric (motor) drive